About a century ago, as telephone lines blanketed the country, signals often withered to noise because the repeaters (amplifiers) varied in quality. Black of Bell Labs invented negative feedback, and amplifier consistency became the norm. Ridding the world of duds only moderately lowered maximum amplifier quality, yet telephones were never audiophile grade. Feedback always creates some form of distortion.

Designing and building the best equipment taxes people and organizations. Some companies tune equipment by soldering in extra capacitors; others remove and replace parts until a product works. Before assembly, Bill Hutchins of LKV Research matches precision components for each channel. Clean and discrete.

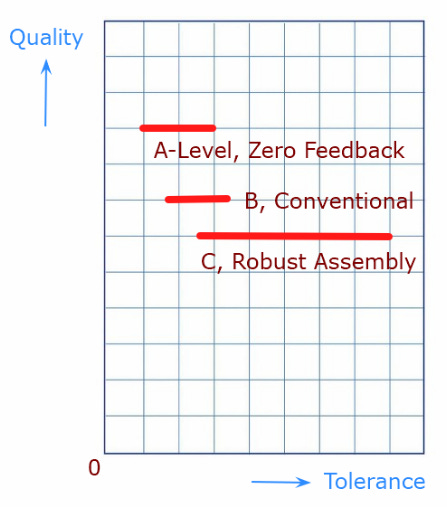

Using opamps with their internal feedback would make work so much easier in design and build, but the amplifiers would never be the best. To put it differently, zero-feedback allows a robust product but not a robust manufacturing process. When I worked as a manufacturing engineer, my procedures, materials, and designs were glorious "C" quality. 20% tolerance resistors are lovely things. Plonk, plonk, plonk. “B” designers using 1% resistors and feedback raised materials costs. Consider the following extremely simplified chart.

"A-Level" products include zero-feedback designs using tight tolerance components, exacting circuits, and careful assembly. Welcome to the world of Bill Hutchins and LKV Research.

The Design Approaches in the Service of One Main Goal

Minimize All Sources of Distortion & Noise

AZF Circuitry

Distortion, not just IMD and THD

Class A Signal Amplification, Class D Speaker Output

Zero Feedback

Matched, Key-Discrete Components

No Opamps in Class A (Opamps use feedback)

No Electrolytics in Signal Paths

Noise

Differential (aka Balanced) Circuitry

Short-Lengths for Signal Paths

Dual-Mono for Minimal Crosstalk*

XLR (aka Balanced) & RCA Inputs & Outputs*

Linear Power Supplies, external supplies on pre-amplifiers.*